experience to be trusted

Ground Improvment Contracting

Consolidation using

Prefabricated vertical drains

Quick installation

Accelerated drainage, shortening construction timelines

Improved quality control through automated monitoring

Effective in deep, challenging soil conditions

Cost-effective

PVDs are particularly useful in low-permeability soils like clay, which normally take years to drain, and are designed to perform even under heavy settlement or deformation conditions.

Compaction using

dynamic compaction

Infrastructure: Used for compacting embankments for roads, railways, and runways, improving load settlement and mitigating liquefaction.

Dredging and Land Reclamation: Compacts reclaimed land to meet stability specifications.

Mining: Enhances roadway strength for heavy trucks and facilitates higher production in spoil fills.

Construction: Prepares terrains for building by improving soil density and settlement behaviour.

Improves a wide range of weak soils, increasing density, friction angle, stiffness, and bearing capacity.

Reduces the need for deep excavation or piling, allowing the use of shallow foundations.

Controlled process with monitoring systems for quality assurance through in-situ testing.

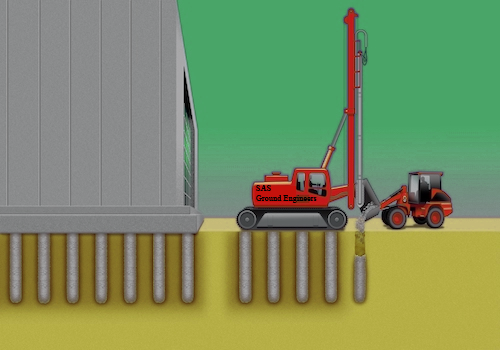

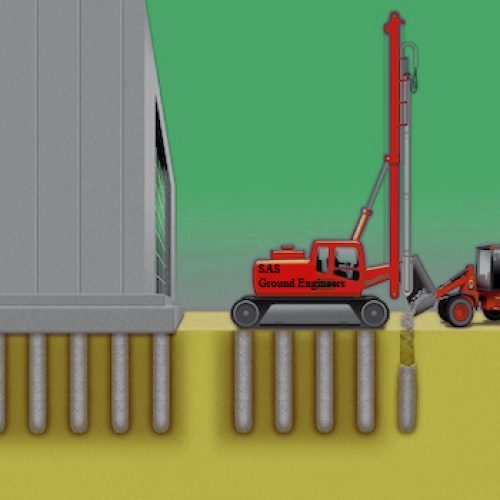

Inclusion Techniques

stone columns

Infrastructure: For building roads, railways, runways, and ports, especially where soil needs strengthening to prevent liquefaction or improve load-bearing capacity.

Dredging and Land Reclamation: Helps avoid the use of sand keys and prevent liquefaction in silty reclamation sites.

Mining: Enhances the stability of roads and infrastructure over sandy tailings.

Construction: Used in foundation works for buildings and embankments, enabling faster construction schedules.

Liquefaction Mitigation: Commonly applied to reduce earthquake-induced risks in soils prone to liquefaction.

Increases soil shear strength and stiffness, enhancing bearing capacity and limiting settlement.

Provides drainage paths that reduce pore water pressure and settlement.

Mitigates liquefaction risks, especially in silty or weak soils.

Enables the use of shallow footings, avoiding the need for deep excavation or piling, and is cost-effective with minimal soil removal.

Versatile, adaptable to various soil types, and environmentally friendly as it uses natural and in-situ materials.

Rigid Inclusions

Industrial, commercial, and residential buildings

Road and rail embankments

Storage tanks and terminals

Warehouses, public buildings, and wind turbines

Enables shallow foundations on weak soils

Increases bearing capacity, even for heavy loads

Efficiently reduces settlement by a factor of 3 to 8

Minimal soil waste and adaptable to various projects

Micropile system

Supporting and underpinning foundations

Stabilizing slopes

Transferring loads

Enhancing the stability of existing structures

Resists compressive, tension, and lateral loads

Suitable for sites with restricted access or low headroom

Minimizes disruption and avoids utility re-routing

Can be customized for complex projects and various soil conditions, including karst geology with erratic rock surfaces and voids

Used in both new constructions and repair/reinforcement of existing foundations

Adaptable to difficult site conditions like steep gradients or confined spaces

Grouting Techniques

The Tube a Manchette (TAM) grouting method utilizes perforated pipes equipped with specialized sleeve grouts. These pipes are inserted into pre-drilled holes, featuring short rubber sleeves (manchettes) that function as one-way valves, allowing grout to flow in only one direction. To inject the grout, a double packer system is employed, which pumps the grout into the manchette tube until the packer reaches the midpoint of the drilled holes. The application of pressure pushes the grout past the rubber sleeves, causing the sleeves to rupture and allowing the grout to permeate the surrounding soil. TAM tubing is installed similarly to small-diameter PVC pipes used for piezometers or monitoring wells. A sonic or mud rotary drill creates the casing, into which the TAM tubing is placed before the casing is removed. If soil collapses around the tubing, it is acceptable; otherwise, a bentonite slurry is used to fill the annular space.

Applications:

Tunnel excavations

Cofferdams

Cohesion-less granular soils

Permeation grouting, also referred to as cement grouting or pressure grouting, is a technique used to fill cracks and voids in soil and rock, as well as to permeate coarse, granular soils with flowable particulate grouts, creating a solidified mass. This low-pressure injection method enhances the strength and reduces the permeability of granular soils. Portland cement or microfine cement grout is injected under pressure through single or multiple port pipes at strategic locations. It is crucial to match the particle size of the grout with the size of the voids to ensure effective permeation. The resulting grouted mass exhibits increased strength, stiffness, and lower permeability.

Applications:

Creating barriers against groundwater flow

Underpinning foundations

Providing support for excavations

Stabilizing and strengthening granular soils

Low mobility (compaction) grouting is a technique that involves injecting low-slump mortar grout to densify loose, granular soils and stabilize subsurface voids or sinkholes. This method is effective for rubble fills, poorly placed fills, collapsible soils, karst conditions, and liquefiable soils. It is often chosen for treatment beneath existing structures since the grout columns do not require direct structural connections to the foundations. The process involves inserting an injection pipe to the desired depth and injecting grout while slowly withdrawing the pipe in lifts, creating overlapping grout bulbs that displace surrounding soils. Sequencing compaction grouting from primary to secondary to tertiary locations enhances its effectiveness, with the high modulus grout columns reinforcing the treatment area.

Applications:

Reducing liquefaction potential

Correcting settlement

increasing bearing capacity

stabilizing or mitigating sinkhole risk.

Jet grouting is a technique that utilizes high-velocity fluid jets to create cemented soil structures of various shapes underground. The process involves a grouting monitor attached to a drill stem that is advanced to the desired depth, where high-velocity jets of cement grout (optionally mixed with water and air) are used to erode and blend the existing soil with the grout while rotating and lifting the drill stem. Depending on the application, different systems may be used: a single fluid system (slurry grout), a double fluid system (slurry grout with an air jet), or a triple fluid system (water jet with air-jet and separate grout port). The resulting soilcrete geometry and properties are tailored to the surrounding soil conditions, with erodibility influencing the outcome.

Applications:

Underpin foundation

Provide excavation support

Seal the bottom of planned excavations

Manage groundwater

Stabilize unstable soils, particularly in areas that are water-bearing.